Following Good Manufacturing Practices involves many sanitation practices, including general cleaning, washing, and sanitizing equipment, and cleaning walls and floors. During the Hazard Analysis, certain hazards may be identified that require specific Sanitation Preventive Controls beyond GMPs in order to minimize or prevent the hazard. There are several potential hazards in peanut processing that might require a preventive control.

- Environmental pathogens such as Salmonella can contaminate products unless facilities are kept sanitary.

- Pathogens can be introduced through cross-contamination from unclean equipment, employees, or raw ingredients.

- Food allergens can also be transferred from equipment that is not cleaned between processing allergen-containing and non-allergen products.

Be aware that some practices that might be listed as a GMP can become a Process Preventive Control if they are needed to address a specific hazard that was identified through the Hazard Analysis process.

Here is an example of a step in the Hazard Analysis of a peanut butter process where a sanitation control was deemed necessary to control potential Salmonella in the environment.

Hazard Analysis needing Sanitation Control

| HAZARD ANAYLSIS | |||||||

|---|---|---|---|---|---|---|---|

| PRODUCT: | PAGE 1 OF __ | ||||||

| FACILITY: | ISSUE DATE: | ||||||

| ADDRESS: | |||||||

| Process Step | Hazard | Preventive Control required? | Justify decision | Preventive controls | Applied at this step? | ||

| Yes | No | Yes | No | ||||

| B – Salmonella in the environment | X | Raw peanuts may contain Salmonella that can contaminate the environment | Zoning and dry cleaning | X | |||

| C | |||||||

| P | |||||||

The team identified Salmonella as a hazard likely to appear in raw peanuts based on scientific studies in the literature and that Salmonella can cause serious illness in humans. So, they decided to use a preventive control to keep the raw peanuts isolated to prevent them from contaminating roasting product and to dry clean.

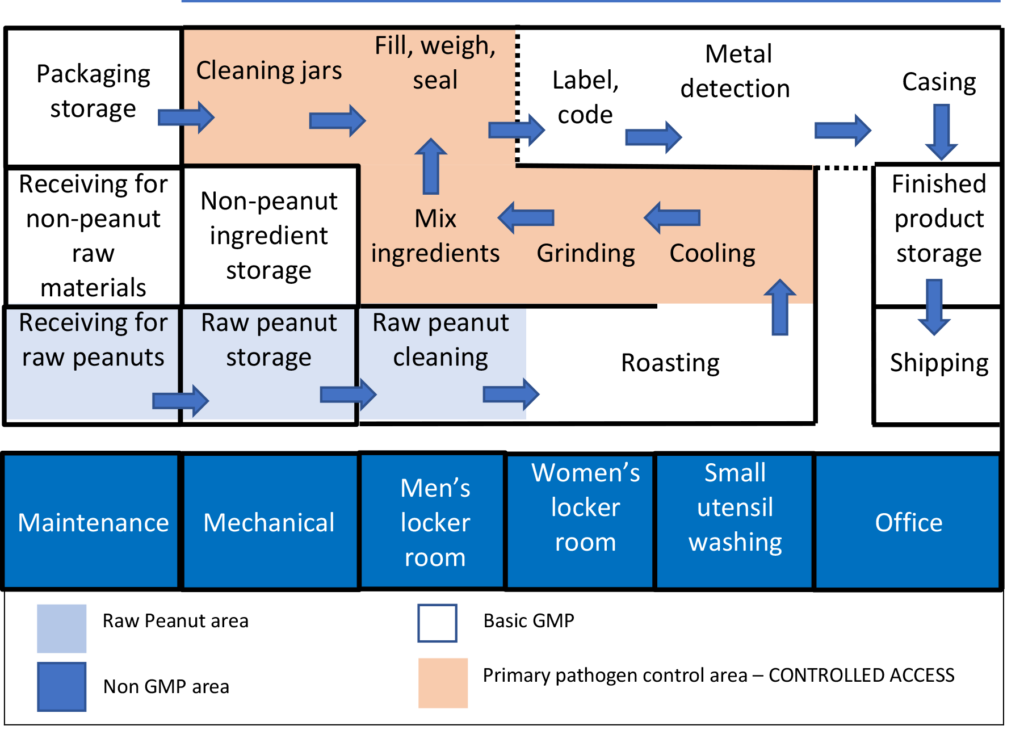

The preventive control above, to provide separate areas to isolate a potential hazard, is a form of hygienic zoning. Facilities can include several areas with different sanitation or isolation requirements. Typically, there are up to five zones.

- Non-manufacturing areas such as maintenance shops, offices, employee areas, and waste disposal areas

- Transition areas such as entry rooms, locker rooms that enter into basic GMP areas

- Areas that require basic GMPs like the spaces where you receive, store, and clean raw ingredients.

- Primary pathogen-control area that has controlled access. This area would be where product is cooked or pasteurized or where RTE products might be exposed to the environment

- Sensitive/high hygiene area with restricted access. This may contain products for sensitive populations such as infants

Different food processing facilities can have very different designs. A large manufacturing company may have the resources to build a linear facility where product flows from one separated area to the next. Other facilities may be small and more open, a situation that is more challenging to control but may be the reality in some places.

When considering a Sanitation Preventive Control, it is important to document how employees will prevent the identified hazard. That documentation may include procedures, practices, and processes to ensure the cleanliness of food-contact surfaces, including utensils and equipment. They also may include procedures to prevent cross-contamination or contamination through unsanitary objects, food packaging material or other food-contact surfaces. A food safety hazard might also involve cross-contamination from raw product to processed product.

In addition to zoning, other preventive controls might be necessary in peanut butter processing. In this example, the food safety team decided that the cooling area after roasting could become contaminated with Salmonella. They felt that in addition to zoning, workers should dry cleaning equipment and the production environment when switching from one product to another to reduce the risk of contaminating product during cooling.

When considering the type of cleaning and sanitation to use in a peanut process to control a hazard, it is very important to remember that Salmonella requires water to grow. Therefore, it is recommended that dry cleaning be used whenever possible. The key is to avoid using water which can allow pathogens to grow.

In dry cleaning, residue is removed with tools such vacuums, scrapers, brushes, and alcohol wipes, while using care to avoid distributing residue into the process. Pressure devices like blowers should be avoided or used very carefully. A worker then inspects to ensure that dry cleaning was effective.

Sometimes dry cleaning cannot remove residues, such as stubborn allergen residues. Before resorting to wet cleaning, a worker should remove as much residue as possible through dry cleaning, then rinse to prepare the surface and loosen residue, wash, rinse again, inspect, and sanitize. Some countries require a rinse after sanitizing. Choosing the correct sanitizer must take into consideration the type of process and the regulations of the country.