Identifying significant food safety hazards depends upon the food, the ingredients, the equipment, the facility layout, and other elements of the facility’s food safety system. Potentially serious food safety hazards must be identified so that preventive controls can be applied to help ensure the safety of the product. A proper hazard analysis should be based on risk and focus on the most important aspects to control. An improper hazard analysis may identify too many controls, areas where hazards are not likely to cause illness or injury; this lack of focus could make it difficult to manage hazards with limited resources. Instead, it is important to perform a hazard analysis, following the steps outlined in this lesson.

Before starting the hazard analysis, identify the personnel who will be responsible. Document the product characteristics and its distribution, write out a description of the intended use and targeted consumers, and develop and verify a process flow diagram. Here is an example of the Product Description.

Product Description

| Product Description | |

|---|---|

| Product Name(s) | Peanut Butter – Creamy, Chunky and Extra Chunky |

| Product Description, including important food safety characteristics | Peanut butter with varying sizes of peanut particulates depending on the variety. Aw < 0.35; pH about 6.3 |

| Ingredients | Peanuts, sugar, hydrogenated vegetable oil and salt |

| Packaging Used | Plastic container, paper/foil induction lid-stock, plastic closure. The headspace of jars is flushed with nitrogen (N2) prior to sealing to delay organoleptic deterioration. |

| Intended Use | The product is ready-to-eat |

| Intended Consumers | General public |

| Shelf Life | Nine months ambient, unopened |

| Labeling Instructions | Contains peanuts |

| Storage and Distribution | Ambient |

| Approved | |

| Date: | 8 August 2015 |

| Signature: | F.S. Leader |

| Printed Name: | F.S. Leader |

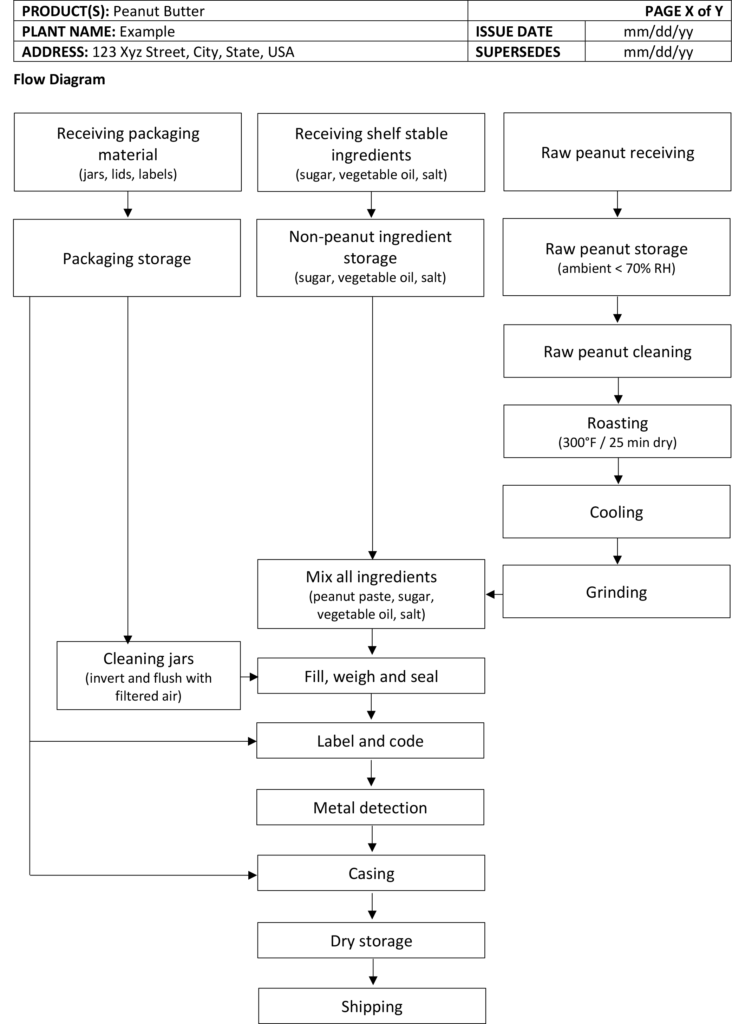

Here is the flow of the process, from receiving packaging and raw materials, through to shipping finished product.